Kakor hjälper oss att leverera våra tjänster. Genom att använda våra tjänster, tillåter du vår användning av kakor.

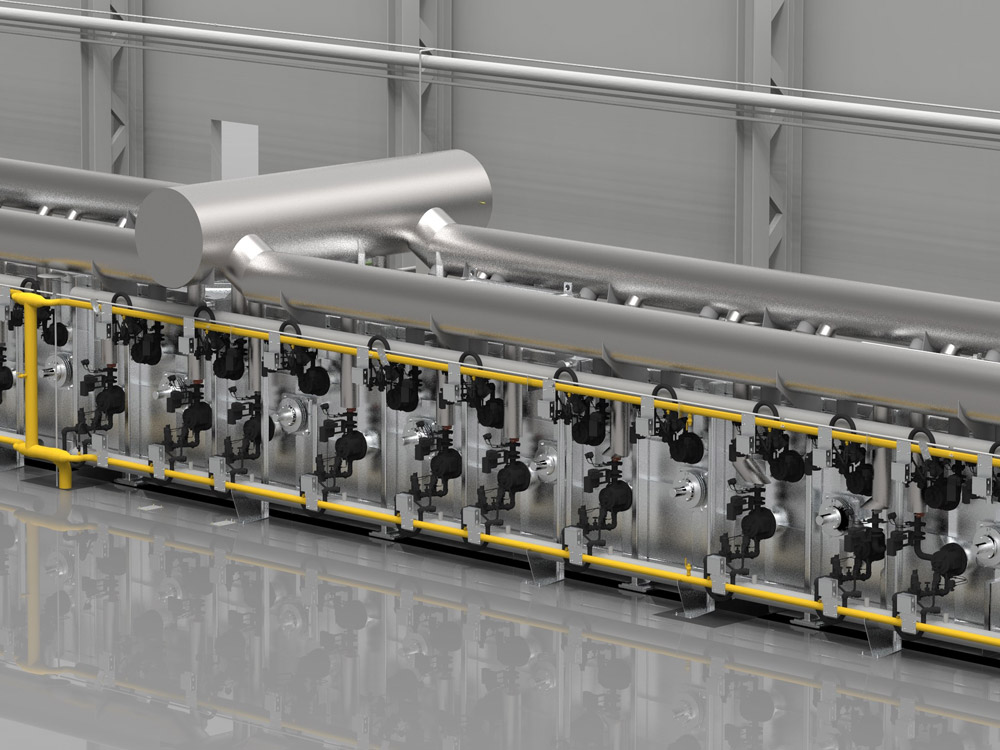

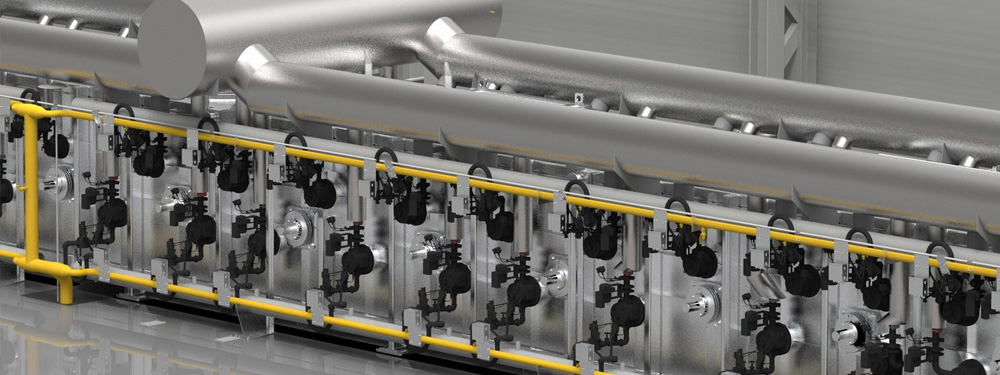

HICON final annealing and coating line (FCL)

HICON final annealing and coating line (FCL).

In the final production step of the heat treatment process for grain-oriented products, an inorganic insulating coating is applied to the material; the material is then dried and sintered in a catenary furnace. This is followed by thermal leveling (thermo-stretching) in a horizontal continuous furnace, which takes place in atmosphere to improve flatness without affecting the magnetic characteristics. The process steps for this phase of production are as follows:

- Multi-stage strip cleaning to remove any MgO residues

- Activation of the surface by pickling, which to optimally conditions the surface for the downstream coating step

- Application of an inorganic insulating coating with a horizontal roller coater

- Drying and sintering of the coating in a catenary furnace

- Thermal leveling in a horizontal continuous furnace, in process atmosphere; the strip is processed at a specified tension to ensure optimal flatness

- Controlled cooling in the slow cooling zone and final cooling zone

- Optional: In-line laser scribing to modify the structure of the magnetic domains

Advantages of the EBNER facility design:

- Controlled thermal leveling provides perfect control over the geometric properties of the final product

- Homogeneous controlled cooling ensures ideal flatness and prevents interior stresses