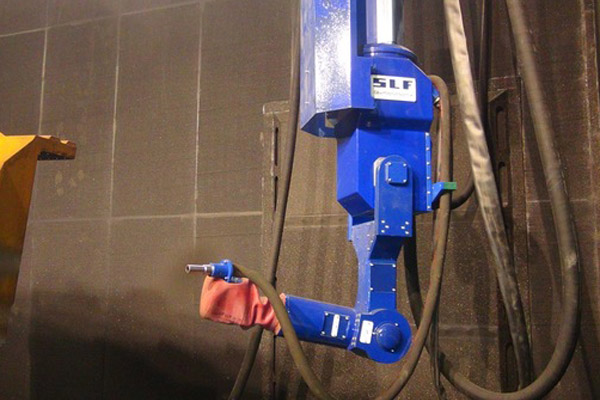

SLF Media Blast Robot ReCo-Blaster®

BLASTING LARGE SERIAL PARTS AUTOMATICALLY BY MEANS OF MEDIA BLAST ROBOT

In order to achieve a more efficient and economical blasting of workpieces, particularly of large serial parts, we have developed the media blast robot ReCo-Blaster®, which in the meantime has well proven for different applications.

The media blast robot ReCo-Blaster® is practice approved

Among the applications of the ReCo-Blaster® there is the automated blasting of components in the aerospace industry and components for wind turbine engineering, of large series parts in conventional steel manufacturing and in foundries, as well as of wagon bodies and railcars in railway vehicle building.

Take the opportunity to optimise your process for the blasting of large serial parts

Under certain conditions the media blast robot can be integrated into your exisiting blastroom.

Don’t hesitate to contact us, should you want to upgrade your process to automated blasting!

Advantages of the media blast robot:

- electric drive without hydraulics

- multiply increased surface treatment rate by larger blast nozzle diameter and higher blasting pressure

- consistent blasting quality and reproducible results by monitoring of all blasting parameters

- very high working and process reliability

- suitable for all types of blast media

- continuous blasting process

- optimum sealing against dust

Control options:

- offline programming

- handheld operating panel

Brochures

The video shows a ReCo-Blaster® in operation in a steel construction company:

Examples

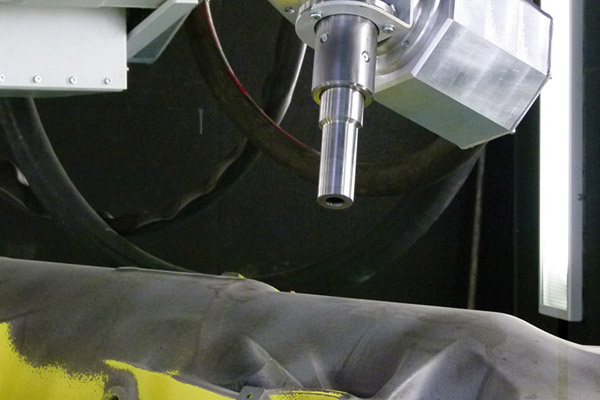

Media blast robot for paint-stripping of landing gear

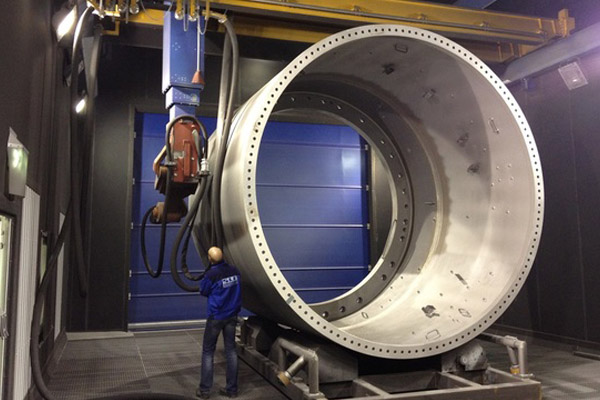

Media blast robot for blasting of wind power plant components

Blastroom with media blast robot for large workpieces