SLF Automated blast machines

AUTOMATED BLAST MACHINES FOR THE TREATMENT OF SMALLER SERIAL COMPONENTS

In the sector of automated blast machines we have focused on serial processes of repeated workpieces allowing an automatic treatment. Such workpieces can be components from the automotive sector (such as gear components, rear axle carriers or similar parts) as well as products from the medical sector or other industry sectors.

Be it cleaning, roughening or peening – automated blast machines from SLF are the number one choice

No matter if you want to clean your workpieces (e.g. removal of welding burrs), roughen or harden (shot peening) them for the following surface coating, we offer you the perfect solution!

We design, build and supply our innovative automated blast machines individually according to your process requirements. From indexing turntable machines to highly complex installations with workpiece identification and workpiece handling system or treatment by means of robot numerous projects have been successfully realised.

Advantages of our automated blast machines at a glance:

- completey surveyed and controlled system functions

- very high workpiece positioning accuracy

- very high repeat accuracy of blasting results

- blasting parameters such as blasting pressure, media flow rate etc. adjustable by remote control

- many more...

Examples

Automated blast machine with index table

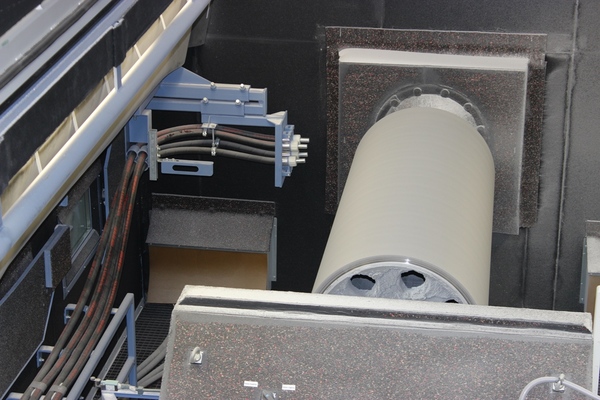

Pressure-blast automated blast machine with workpiece handling via robot

Pressure-blast automated blast machine with four nozzles for blasting of drums